Reorder Point

Introduction

Efficient inventory management is a critical aspect of enterprise asset management, ensuring that spare parts and essential components are available when required. IBM Maximo, a leading Enterprise Asset Management (EAM) system, offers a robust platform for managing inventory, but traditional methods often struggle with real-time data updates and predictive maintenance needs. By integrating Watson X for chatbot and FASTAPI for seamless API communication, this solution enhances inventory optimization, reduces operational costs, and improves asset maintenance efficiency.

Overview

Inventory management plays a crucial role in optimizing operational efficiency by ensuring that spare parts and other critical components are available when needed. This documentation outlines the challenges, solutions, and benefits of implementing an intelligent inventory management system using Maximo Manage and WatsonX. Additionally, it discusses the role of FASTAPI for API communication to facilitate real-time data exchange.

Inventory Management

Inventory management is the process of ordering, storing, using, and tracking a company’s inventory. This includes managing raw materials, components, and finished products, as well as warehousing and processing such items. In the context of enterprise asset management, inventory management ensures that assets have the necessary parts available to minimize downtime and optimize performance.

Importance of Inventory Management in Maximo

IBM Maximo is a leading enterprise asset management (EAM) system that provides comprehensive asset lifecycle and maintenance management capabilities. Effective inventory management in Maximo ensures:

- Optimized Spare Parts Availability: Ensures that critical components are always available when needed.

- Cost Reduction: Prevents overstocking and stockouts, reducing unnecessary expenses.

- Improved Maintenance Efficiency: Ensures timely repair and maintenance by having the right parts at the right time.

- Minimized Asset Downtime: Reduces equipment failure due to missing spare parts.

- Accurate Tracking and Reporting: Provides real-time insights into inventory levels and consumption trends.

Challenges in Inventory Management

- Identifying the Optimal Reorder Point

- Determining when to reorder spare parts to prevent shortages without overstocking.

- Inability to Respond to Real-Time Changes

- Traditional systems fail to adjust dynamically based on real-time asset conditions.

- Ineffective Handling of Large Inventories

- Manual tracking is inefficient for large inventories, leading to mismanagement.

- Time-Consuming Process when Done by Humans

- Manual data entry and analysis slow down operations.

- Spare Part Shortage Challenges

- Lack of spare parts can lead to asset downtime and operational delays.

- Human Errors

- Miscalculations and mismanagement due to human intervention.

Proposed Solution

To overcome these challenges, an approach with historical data analytics is proposed.

Key Components of the Solution

- Building an agent for Reorder Point Calculation

- The agent extracts details from historical data to determine the optimal reorder point.

- Automated Data Extraction from Historical Work Orders

- Work orders related to specific item numbers are analysed to identify consumption trends.

- Spare Parts Consumption Pattern Analysis

- The system predicts future spare part requirements based on past usage patterns.

- Accurate Consumption Rate Calculation

- Predicts the rate at which spare parts are used to ensure timely restocking.

- Dynamic Reorder Point Adjustment

- The reorder point is adjusted dynamically based on real-time conditions and predictive analytics.

Integration with FASTAPI for API Communication

To facilitate seamless communication between the inventory management system and Maximo, we use FASTAPI. FASTAPI is a modern, high-performance web framework for building APIs with Python.

Benefits of Using FASTAPI

- Fast and Efficient: Built on ASGI, it supports asynchronous operations for high-speed data processing.

- Automatic API Documentation: Generates interactive API documentation using Open API and Swagger.

- Data Validation: Ensures data consistency using Pydantic models.

- Scalability: Supports high-concurrency operations for large-scale enterprise applications.

Benefits of the Solution

- Minimized Downtime Costs

- Reduces asset downtime by ensuring the availability of critical spare parts.

- Reduced Inventory Holding Costs

- Minimizes the cost of storing and managing spare parts efficiently.

- Optimized Workflows in Maximo

- Reduces manual transactions, improving operational efficiency in Maximo.

- Optimized Use of Inventory Space

- Ensures that only necessary items are stored, freeing up valuable space.

- Real-Time Inventory Insights

- Provides visibility into inventory levels, trends, and reorder requirements.

User Roles & Login

The MAS (Maximo application suite) supports role-based access aligned with Maximo’s permissions:

Roles

- Premium user: A user with full access to critical applications, configurations, and administrative functions. Often equivalent to system administrators or power users who manage workflows, security, and integrations. Can create new security groups, modify workflows, and integrate with external systems.

- Base User: A standard business user with access to core applications for day-to-day operations. Focused on transactional tasks like creating work orders, managing assets, or processing inventory. Can create a work order but cannot approve it (requires PLANNER role).

- Limited User: A user with restricted access, often read-only or limited to specific tasks. Typically used for auditors, temporary staff, or roles requiring minimal interaction. Can view asset history but cannot edit fields.

- Self-Service User: A non-technical user who interacts with Maximo through simplified portals (e.g., Service Request Manager, Employee Center). Typically, external stakeholders like employees, vendors, or customers. Can submit a ticket via a portal but cannot log into the Maximo UI.

Login Process

- Navigate to Maximo Application suite.

- Enter credentials:

- Username

- Password

- Optional: Show Password to verify input

- Click Login to access the Maximo application with Watson X assistant.

- Use Forgot Password to reset credentials.

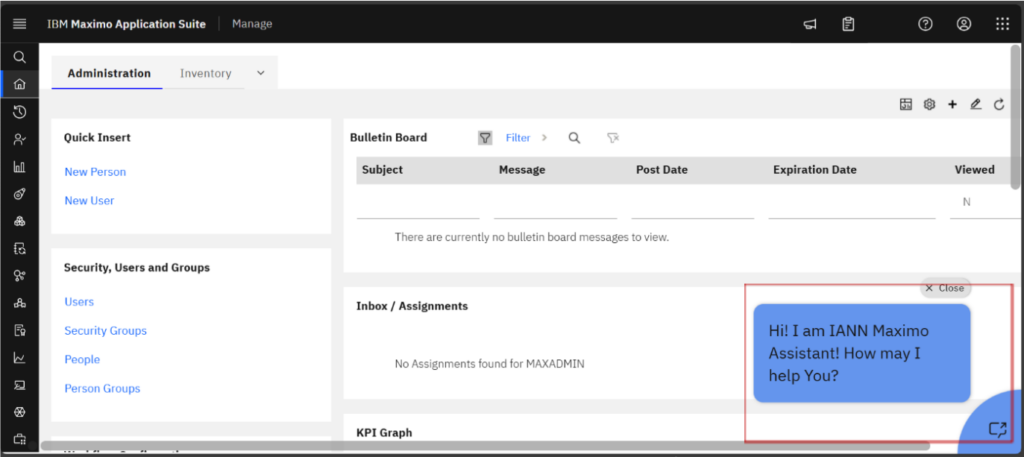

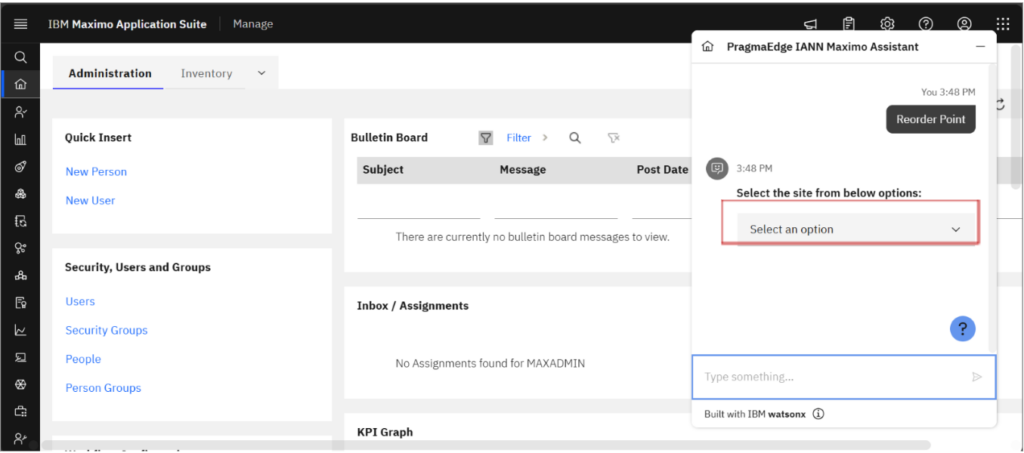

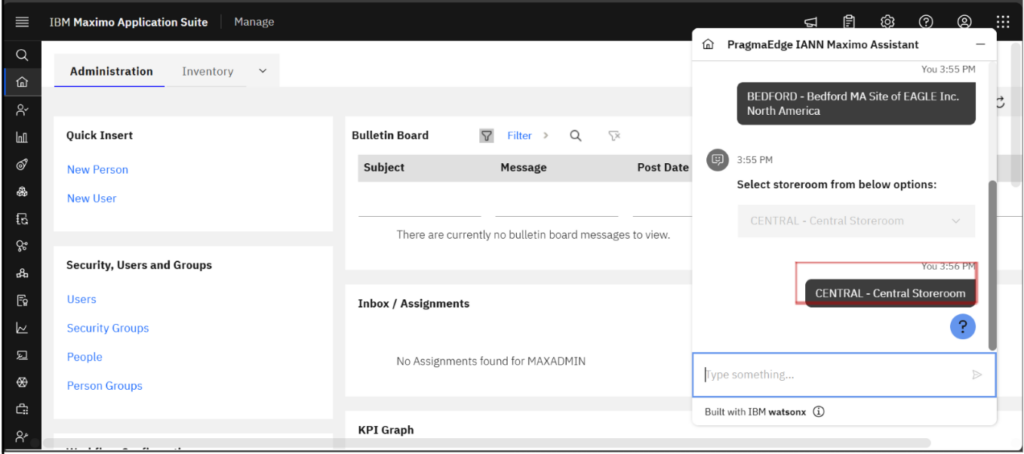

Launch the IANN Maximo Assistant by clicking on the assistant icon.

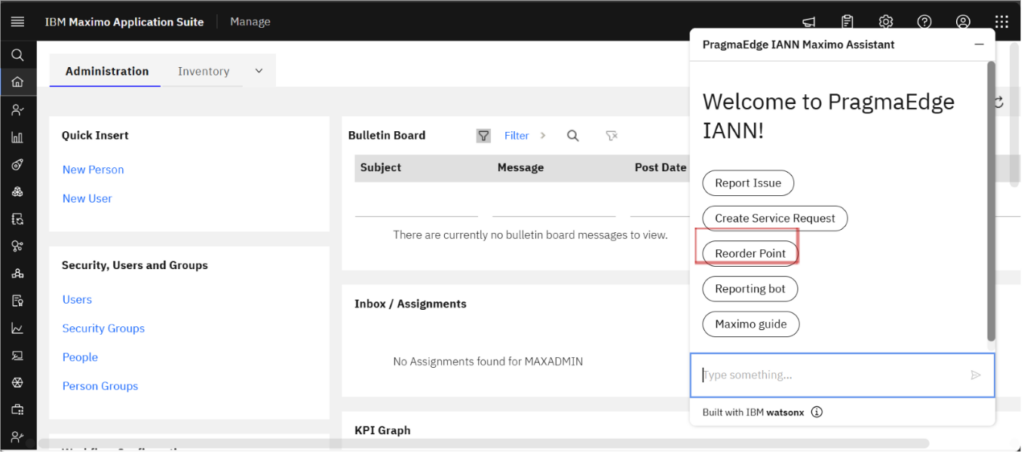

Initiate the process by clicking on ‘Reorder point.’

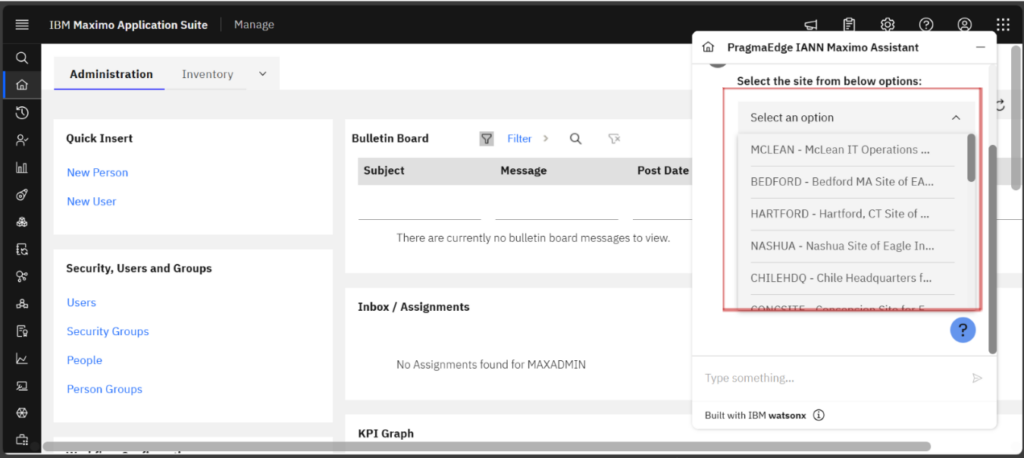

The IANN Maximo Assistant then prompts user to choose site from the below options

We can view all the sites from the Maximo application along with their descriptions.

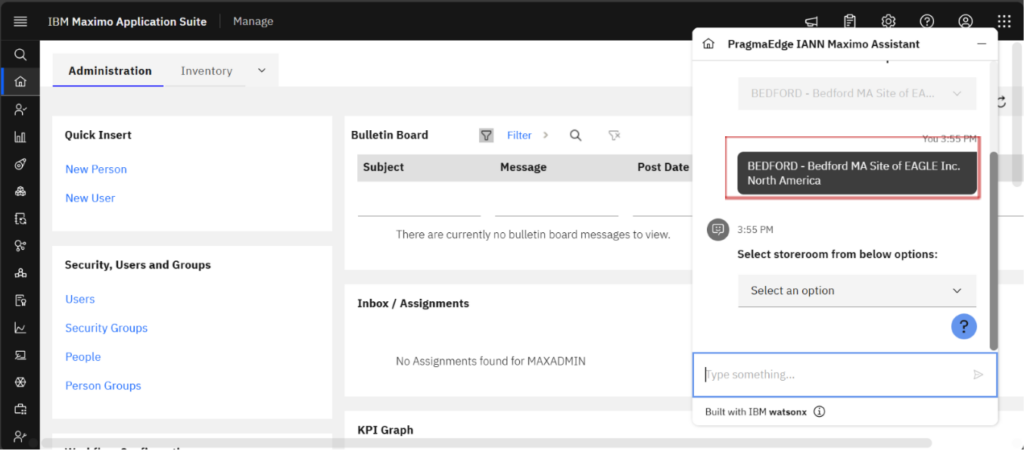

The BEDFORD site has been selected as the designated site.

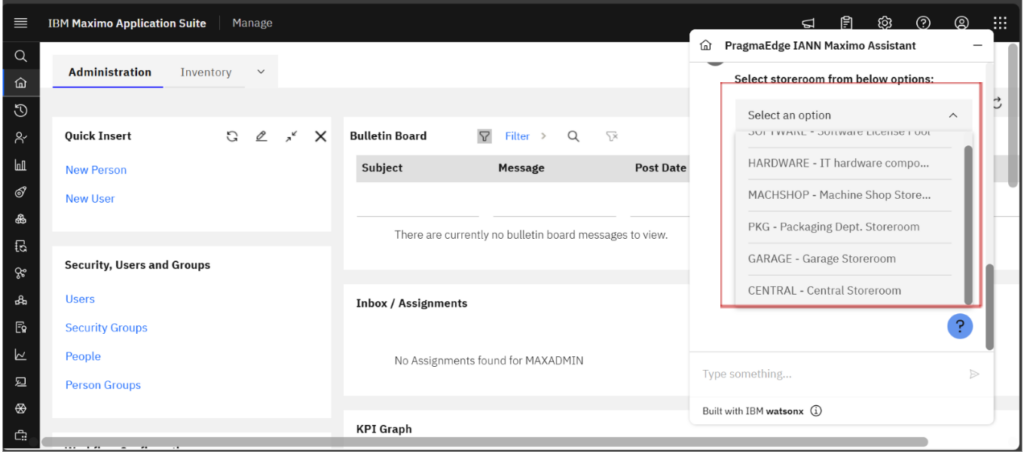

Once you’ve selected the site, the IANN Maximo Assistant will guide you to choose a storeroom from the available options for the BEDFORD site.

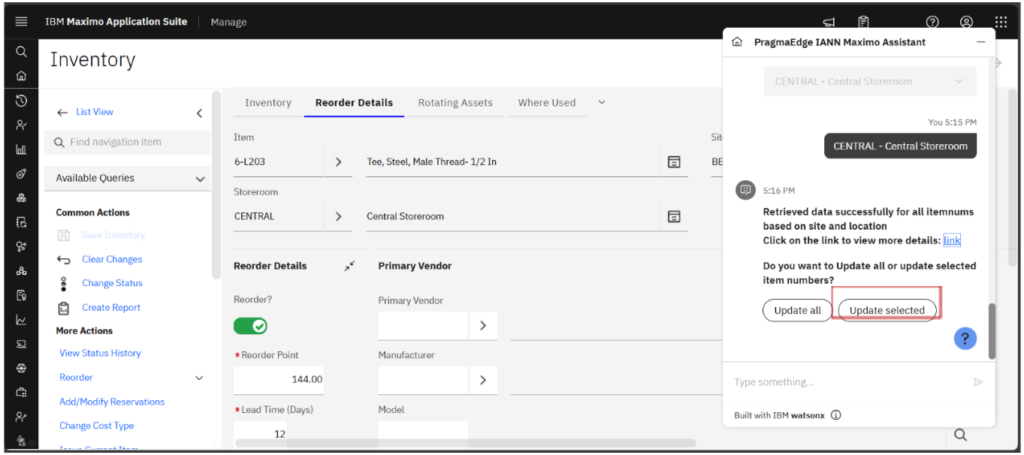

The CENTRAL storeroom has been selected as the designated storeroom.

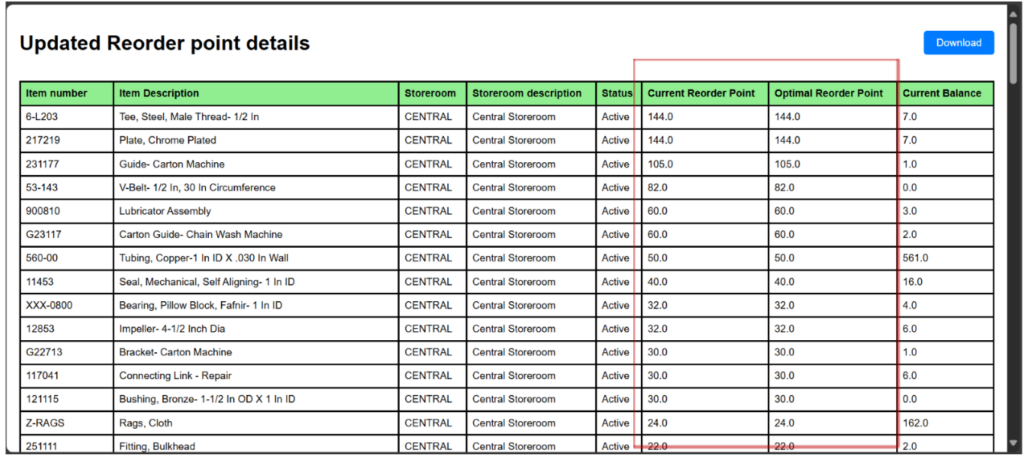

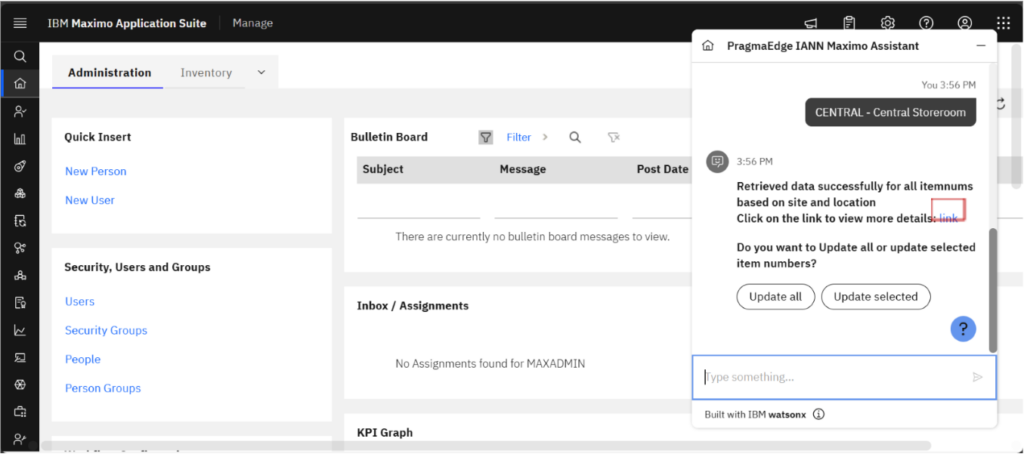

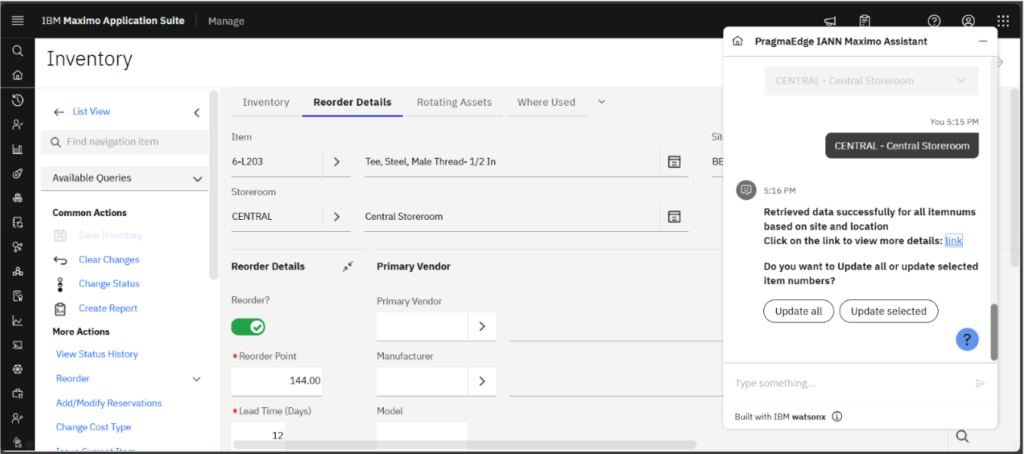

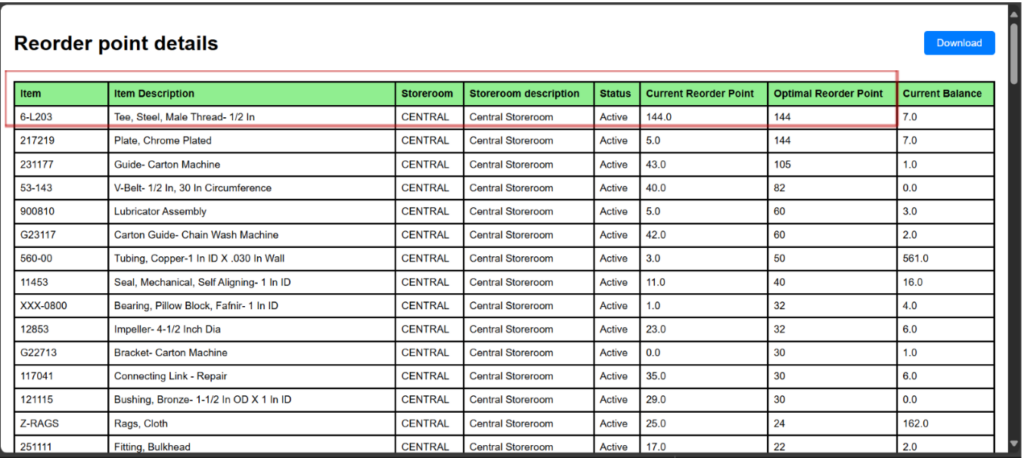

We can see that the agent has successfully retrieved the reorder points data. Simply click the link to view the full details.

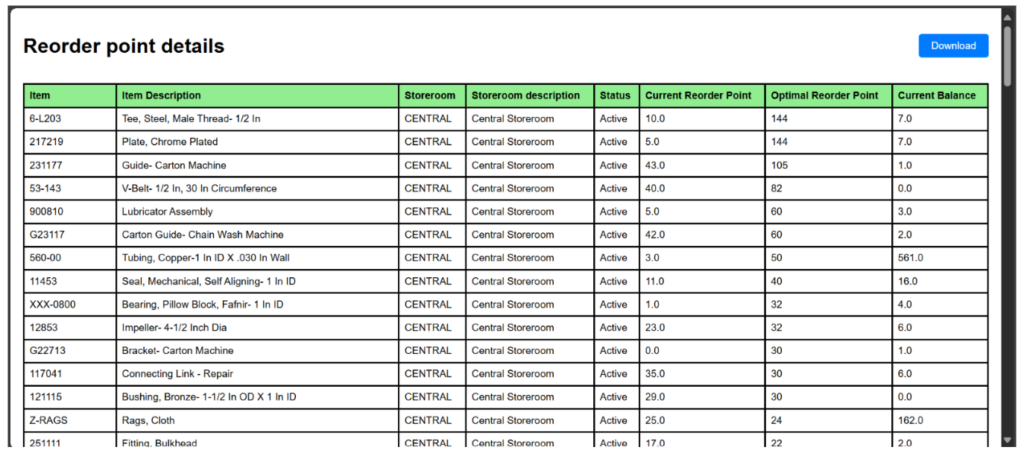

We can see the reorder point details of the central storeroom. It consists of details such as Item, Description of the item, storeroom, description of the storeroom, status of the item, Current reorder point, optimal reorder point, Current Stock Balance of the item as shown in the figure.

For item 6-L203 Current reorder point is 10 and Optimal reorder point is 144.

For item 217219 Current reorder point is 5 and Optimal reorder point is 144.

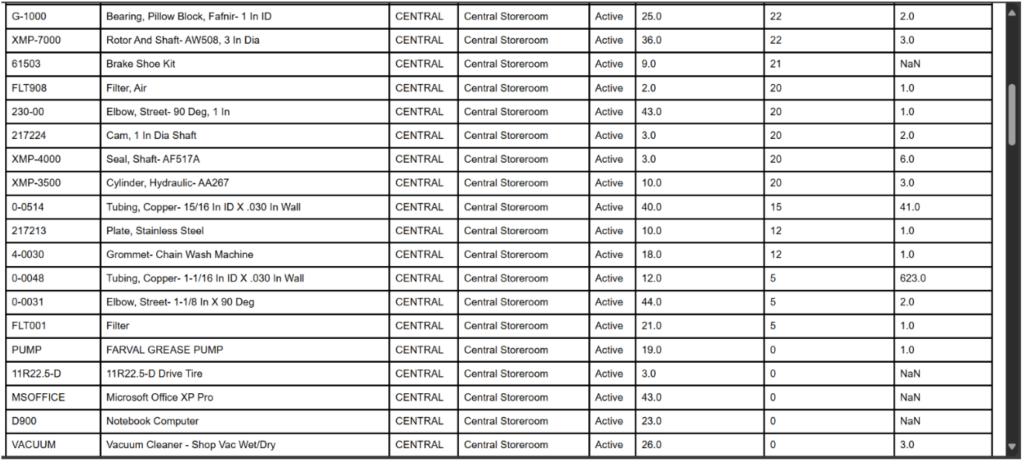

For all the items in the storeroom we fetched the current reorder point and optimal reorder point.

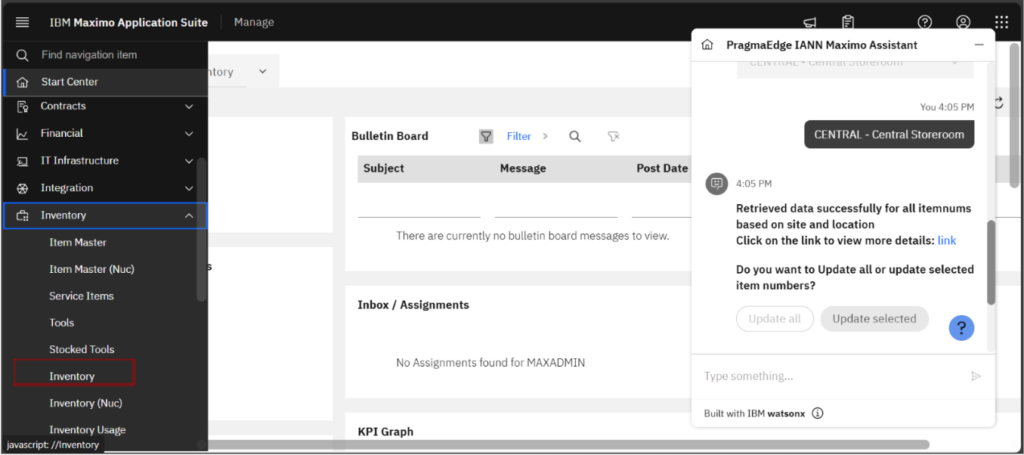

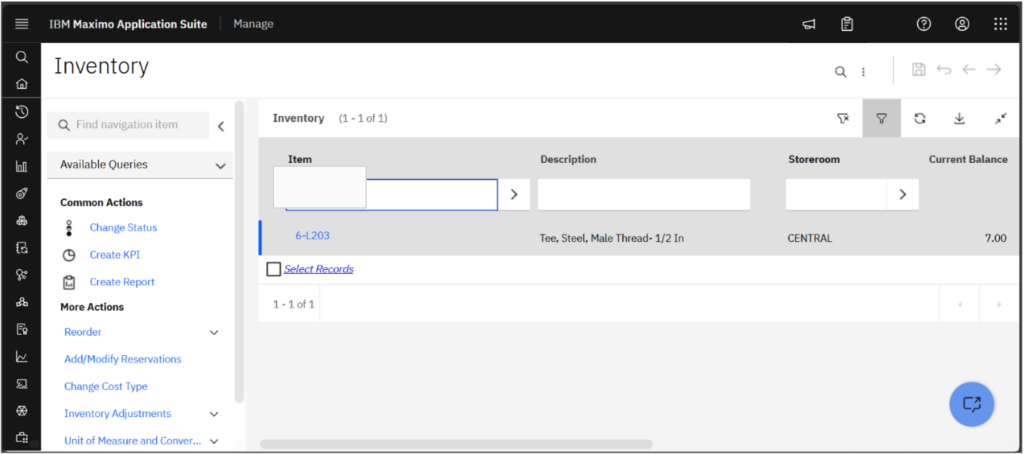

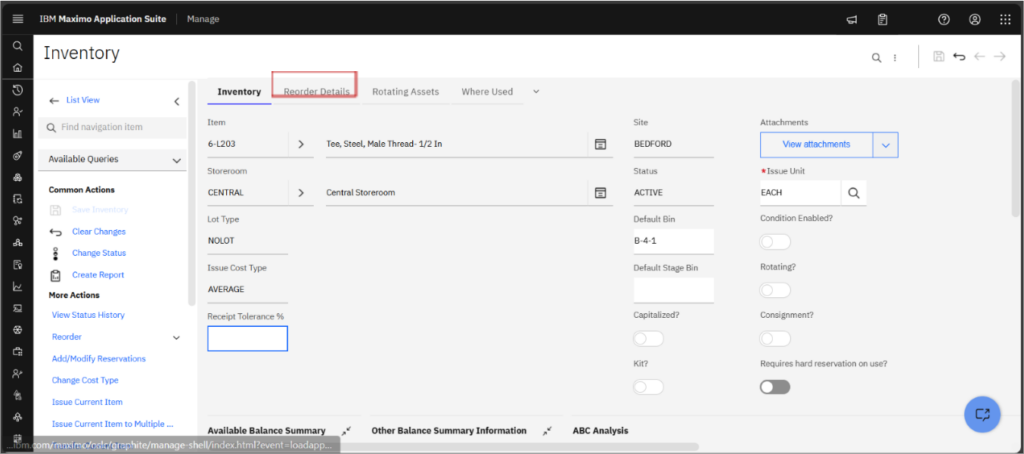

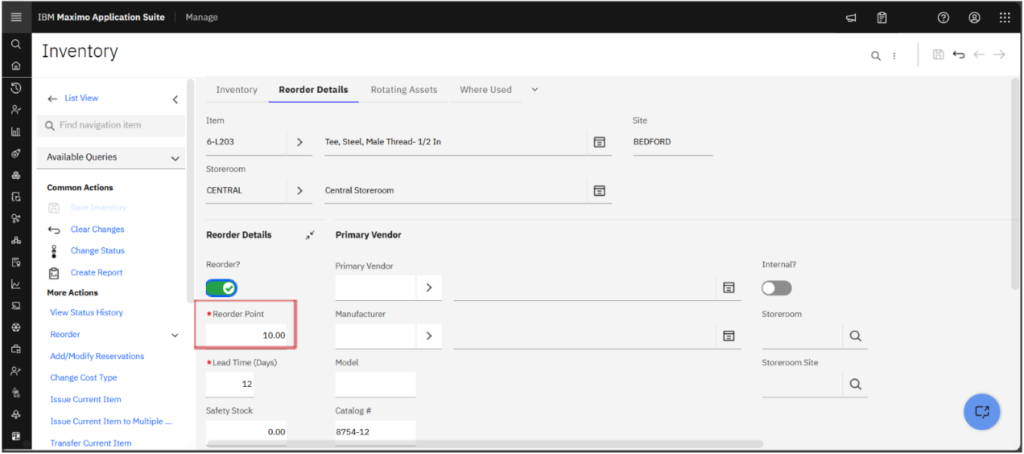

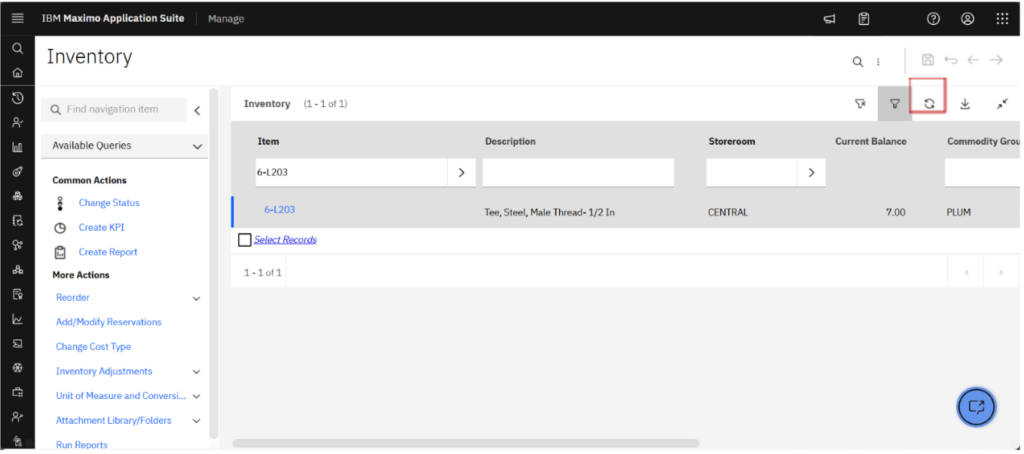

Navigate to the Inventory Application in Maximo to validate the retrieved details.

Provide item number.

Click on the Reorder Details tab. The system displays the current reorder point as displayed in the fetched data.

The fetched data matches the records available in the application.

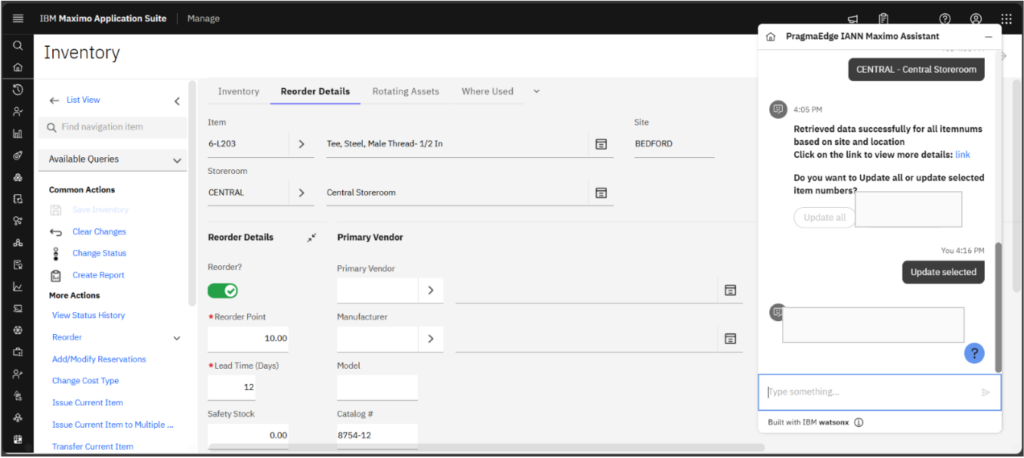

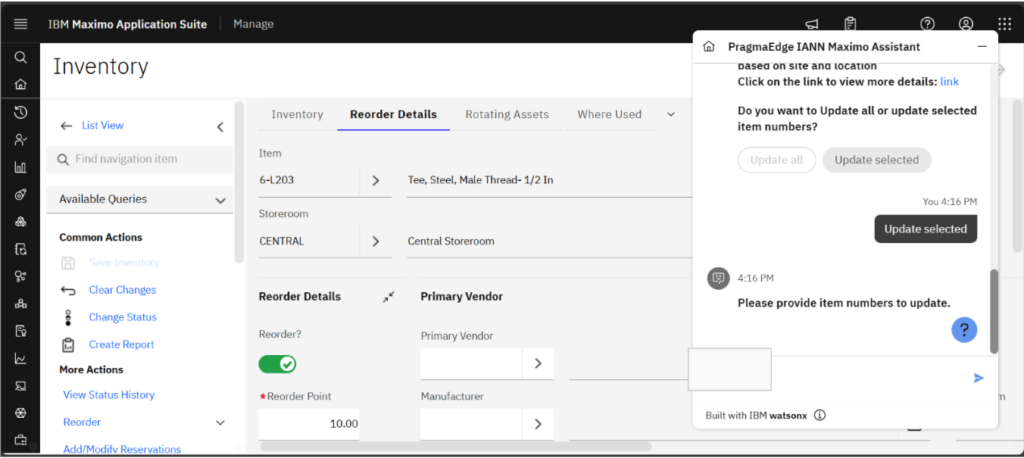

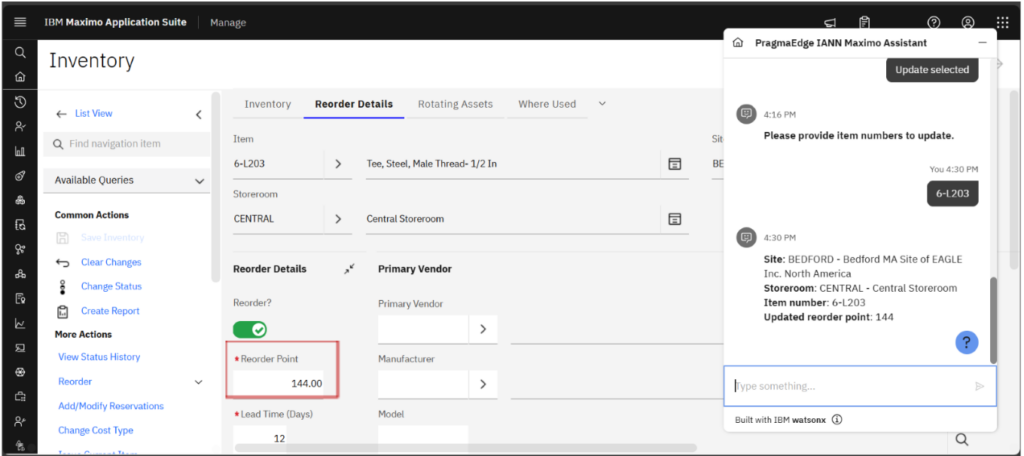

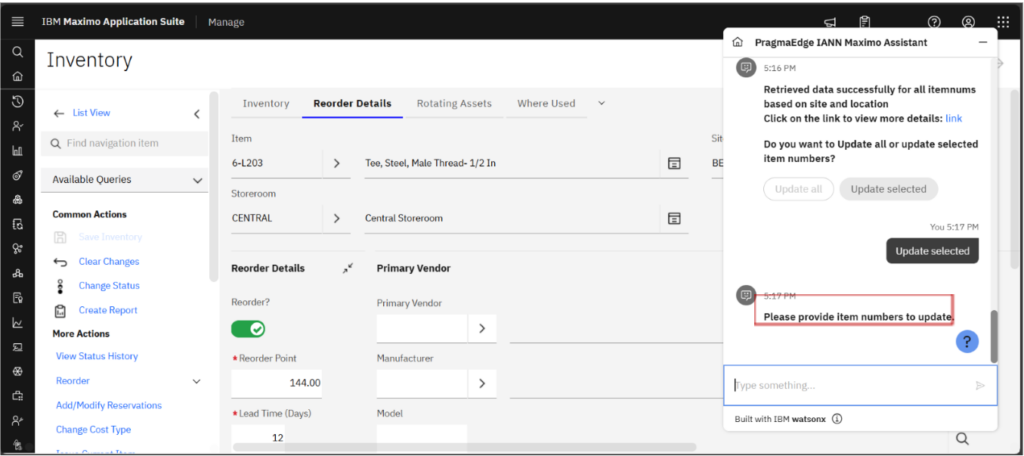

Click Update Selected, and the Assistant prompts for item numbers to update.

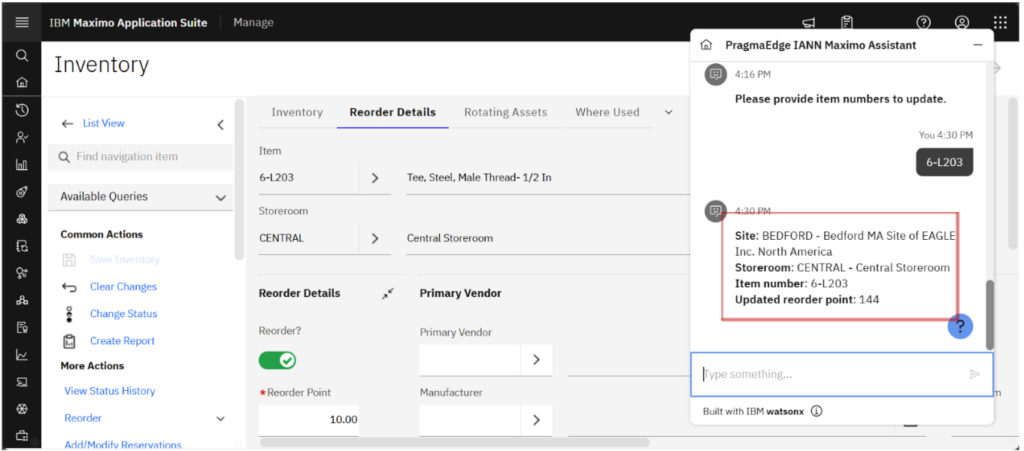

After providing the item number, the Assistant updates the value to its optimal reorder point.

The Current reorder point has been successfully updated to its Optimal reorder point as shown in the figure below.

Refresh the Inventory Application to verify the updated reorder point.

The system confirms that the reorder point has been successfully updated to its optimal value.

We can see item 6-L203 current value and optimal value are same.

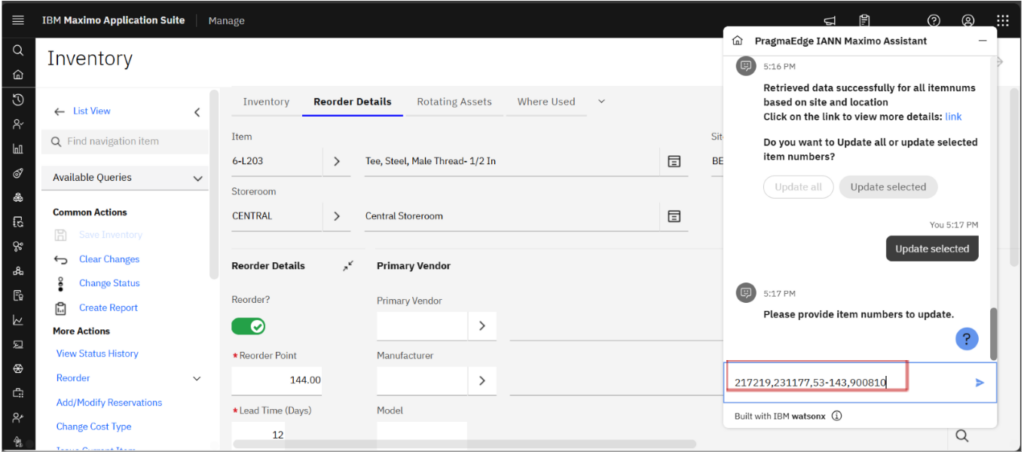

To update multiple items, select Update Selected for multiple items.

The assistant prompts the user to provide item numbers for updating.

Enter the required item numbers and proceed with the update process.

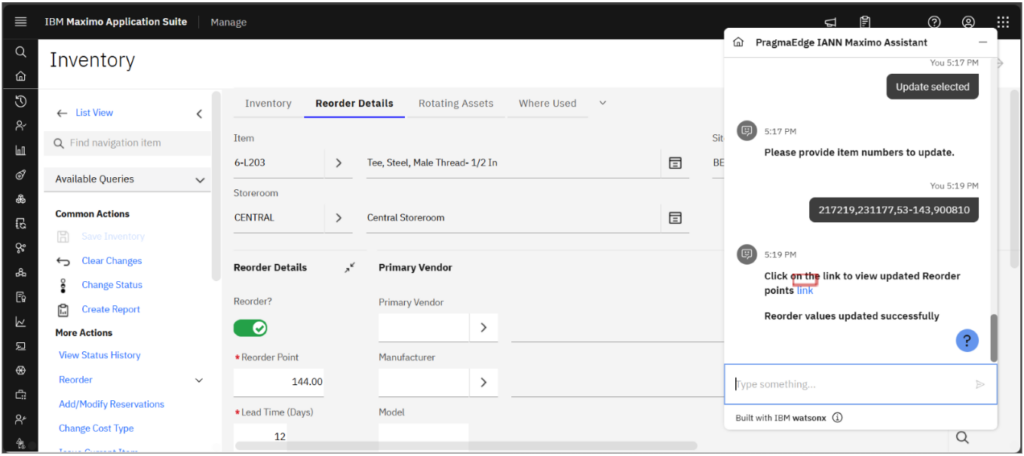

Click on the provided link to view the updated reorder point details.

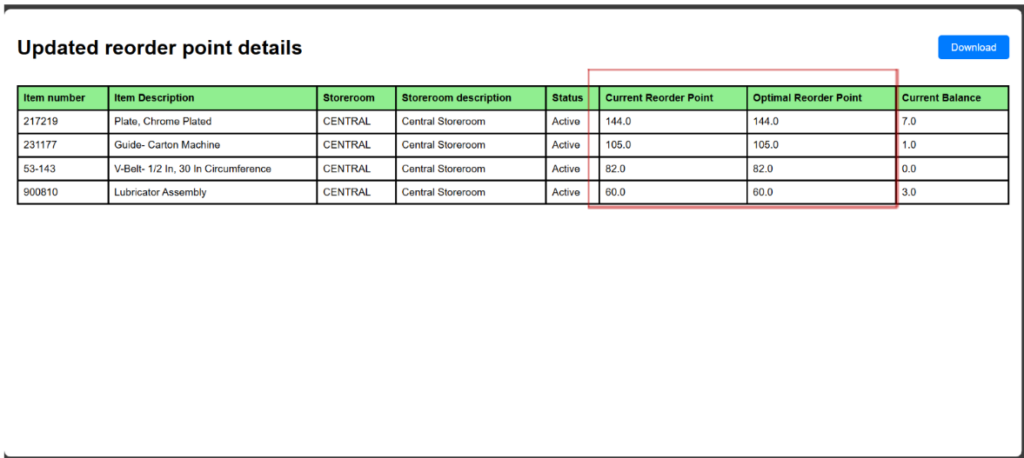

Since we selected four items for the update, we can see their current reorder point is updated to their optimal reorder points reflected in the table.

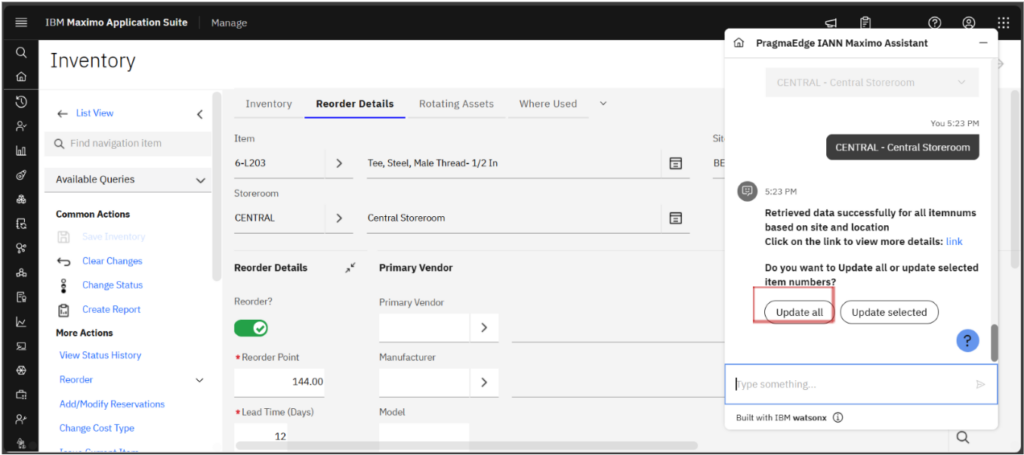

To update all items simultaneously, select Update All in the Assistant.

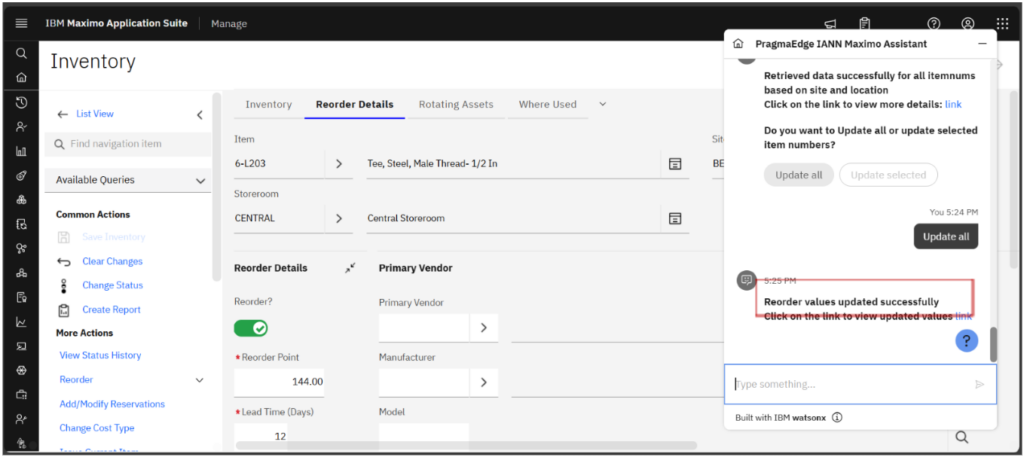

The system processes the request and updates all reorder points to their optimal values. We can see that the reorder points were updated successfully. Click on the link provided to confirm the updated reorder points.

After completing the update process, all items now reflect their optimal reorder points, ensuring proper inventory management.